Choosing the right steel materials for your project can dramatically influence its success, durability, and cost-efficiency. Whether you are working on a structural framework, automotive component, or industrial tool, steel offers a diverse range of properties that can be matched precisely to your application. The key lies in understanding both the different types of steel and the best practices in selecting them. Steel comes in various forms carbon steel, alloy steel, stainless steel, and tool steel each with distinct advantages. Carbon steel, for instance, is highly durable and cost-effective, making it ideal for structural applications such as buildings and bridges. Low carbon steel is easy to weld and form, while high carbon steel is stronger and harder, though more brittle. Alloy steels, enhanced with elements like chromium, nickel, and molybdenum, are designed to improve specific properties such as strength, toughness, or resistance to wear and corrosion. Stainless steel, known for its corrosion resistance and aesthetic appeal, is a popular choice in environments exposed to moisture, chemicals, or high temperatures, such as kitchens, hospitals, and chemical plants.

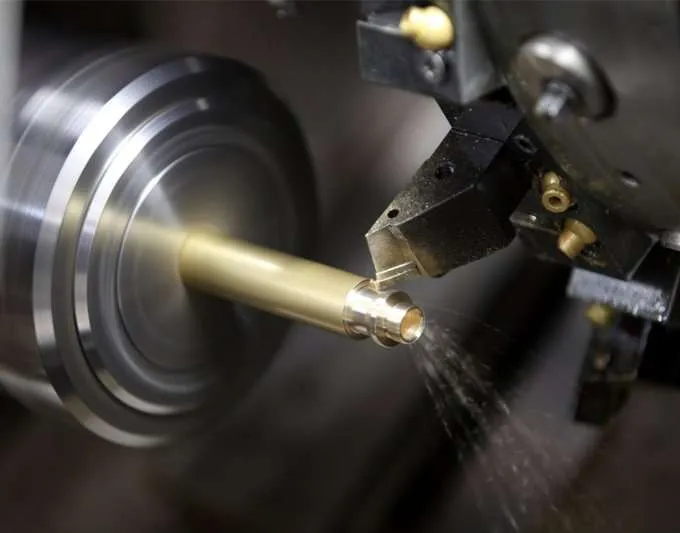

Tool steels are specialized for making cutting and shaping tools, thanks to their ability to maintain sharp edges and withstand high heat and impact. One of the most important best practices in selecting steel is to start with a clear understanding of the environment the material will face. For instance, in coastal areas or highly humid environments, corrosion resistance becomes critical, making stainless steel or galvanized steel a preferable choice. Similarly, projects involving high temperatures or heavy mechanical stress might benefit from high-performance alloy steel turned parts. Understanding the specific requirements for strength, ductility, formability, and resistance to fatigue or wear can help narrow down the most suitable grade. Another crucial step in the selection process is balancing performance with cost. While high-performance steels may offer superior properties, they can be significantly more expensive. It is important to assess whether the added performance justifies the extra cost. In many cases, a mid-range alloy or treated carbon steel can provide an optimal balance between strength and affordability.

Consulting with material engineers or using selection software can help align project demands with material capabilities, ensuring neither under-specification nor over-engineering occurs. Fabrication processes should also guide your steel choice. Uneed steels respond better to machining, welding, or forming. For example, low carbon steels are excellent for welding, while certain tool steels may be too brittle for complex shaping. Thermal treatment is another consideration. If the steel needs to be hardened or tempered, selecting a grade that responds well to heat treatment becomes essential. Ultimately, choosing the right steel material involves a strategic blend of knowledge, foresight, and technical understanding. By carefully evaluating the mechanical requirements, environmental exposure, cost considerations, and fabrication needs of your project, you can select a steel that enhances performance, ensures longevity, and contributes to overall project success. The result is not only a structurally sound product but one that delivers long-term value and reliability.